TERMINAL AUTOMATION SYSTEM: OIL DEPOT SUPERVISION SYSTEM

full control of oil and liquid product loading

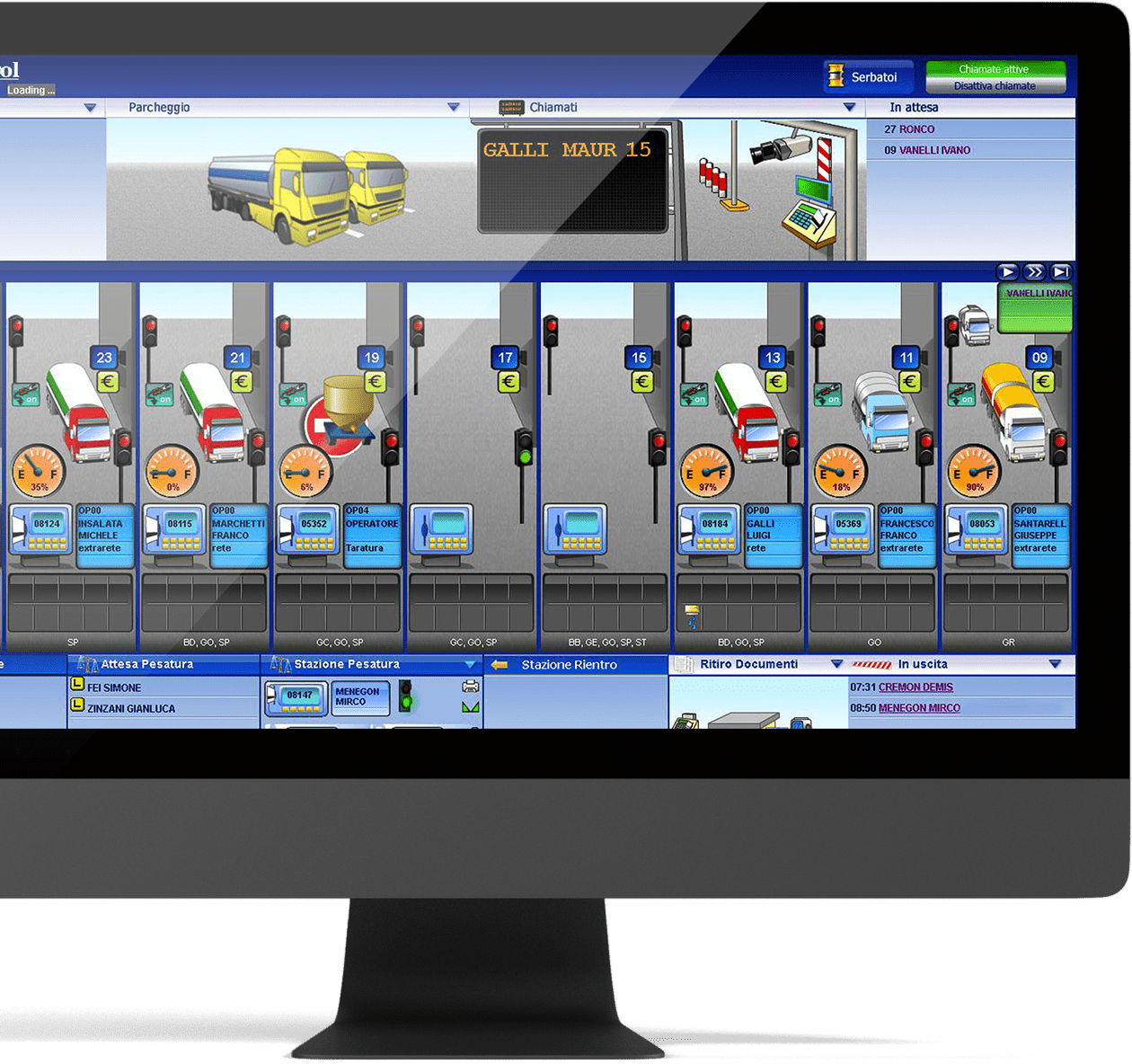

The newly developed Terminal Automation System (TAS) NUOVO PETROL completely supervises and controls the loading and unloading processes within storage and shipping facilities of oil and fluid products. TAS NUOVO PETROL is based on a client-server architecture, and it is developed with modern, open-source technologies chosen from the market’s leading standards. TAS, which can be used on a simple browser for navigation, provides an overview of the automation process for loading and unloading fluid, semi-fluid and dense products, which are handled in a variety of ways (via road, rail tankers and barges).

TAS FOR FLUID DISTRIBUTION SYSTEMS

the Terminal Automation System that supervises and manages depot operations

Nuovo Petrol is the TMS software platform that is modular and configurable on the basis of specific functional requirements and/or system configurations, designed for the automatic supervision and control of the loading and shipping of fluid products. Nuovo Petrol terminal management system allows you to drastically simplify depot management, offering a complete digital overview of the depot, guiding users (operators and drivers) in the right sequence of operational phases.

A TAS WITH SIMPLE AND ACCESSIBLE TECHNOLOGY

a modern technological development on an agile engineering model

From a technical point of view, NUOVO PETROL is a web application developed using the most modern object-oriented programming tools.

This makes the application accessible from any networked location using a simple browser.

MULTI-TIER CLIENT-SERVER ARCHITECTURE

DATA PERSISTENCE ON A RELATIONAL DATABASE

WIDESPREAD OPEN-SOURCE TECHNOLOGIES

LIGHTWEIGHT CLIENT WITH BROWSER NAVIGATION

MAIN FUNCTIONALITIES OF THE TERMINAL AUTOMATION SYSTEM

a newly developed TAS, which allows total management of the loading and unloading process of oil products and handled fluids.

NUOVO PETROL is a supervision system for oil depots that can be integrated with company softwares, guaranteeing identification of driver and vehicle at every required point, allowing easier control of transits and tanker loading / unloading operations.

Scheduling of loading/unloading/shipping

Interface with Management System/ERP: integration with company management software, facilitating the information flow between field supervision systems (TAS) and management systems for smooth and efficient control of shipment scheduling and acquisition of final data for accounting and tax purposes.

Shipment scheduling is received by NUOVO PETROL automatically.

In the absence of a connection with the management system, the scheduling of shipments can be defined directly in NUOVO PETROL through a specific operational procedure.

Driver identification

At each required point, driver identification can take place via contactless electronic badge reader (RFID) or biometric reader, guaranteeing high levels of safety and traceability.

Vehicle identification

Vehicle identification is managed by cameras equipped with automatic number plate recognition technology, ensuring fast and error-free vehicle identification.

These are ANPR (Automatic Number Plate Recognition) and LPR (License Plate Recognition) cameras, designed to capture vehicle number plates. Models with OCR (Optical Character Recognition) can also identify licence plate characters and compare them with an internal database by reviewing Blacklists and Whitelists.

In addition, identification can take place with LONG TAG RECOGNITION solutions (telepass type) and RFID tags installed on the vehicles.

Booking and call-to-load

The driver can signal his arrival at the storage facility by biometric fingerprint reading, or by vehicle or driver badge reading. It is possible to install an interactive booking TOTEM functioning as a stand-alone station including a load sheet printer, identification readers, and monitor.

Load booking can be managed through dedicated totems and/or through the mobile application FLUID (Fast Loading Utility for Intelligent Distribution) which allows booking directly via smartphone.

Tank monitoring

Enables continuous and automated monitoring of the levels in the storage tanks through the interface with the tank gauging system.

Loading grid and call

After verifying the presence of a scheduled load for the driver and a suitable free bay for the type of load, the system will prompt the driver to enter the depot through the dedicated monitor in the driver’s waiting room, a variable message panel in the tanker truck parking lot, or via voice synthesis.

The loading grid is the list of scheduled shipments for a specific day, each associated with the time from which the driver can load (call time) and the loading bay (optional).

In doing so, operators can optimise the time sequence of vehicle access and establish the loading bay in advance, if the system is unable to identify it automatically.

The grid time can be determined in one of the following ways: generated at the same time as the shipment planning (it is one of the shipment data), defined by the depot operator who can change the grid time for scheduled shipment and forced through the system at a predefined time, if not defined in advance.

Access control (e/x)

In the storage area, various vehicle and driver identification devices such as cameras, proximity readers, and biometric fingerprint readers are used to control and validate access and exit.

Control of weighing station (tare/gross)

When applicable, the NUOVO PETROL System can acquire the weights recorded by the tare and gross weighing station.

The driver and tanker identification is carried out in the same way as for entry and exit; i.e., with a number plate recognition camera, proximity badge reader, and biometric reader.

The weight measurements acquired are validated by Nuovo Petrol before authorising the continuation of the operational phases.

Loading/unloading bay control

The loading of products in the bays, which are controlled by TAS Nuovo Petrol, is carried out by the drivers that operate and interact with the system via control terminals in the loading bays (GraL).

Once the bay terminal receives the quantities programmed for loading from the system, the driver autonomously subdivides the programmed quantity according to individual presets, using the terminal keyboard and display.

Once the loading phase is over, the bay terminal sends the load data to TAS Nuovo Petrol, which forwards them to the management system.

Loading operations can be carried out in automatic or manual mode.

In an automatic operation, loading operations are controlled by the system.

In addition to managing driver directives (START, STOP commands, individual preset valorisation), the bay terminal, when foreseen, controls the various loading consents, including: Earthing and overfill prevention connection, Vapour Recovery Unit (VRU) connection, Emergency button, Arm position.

The signals inhibit the start of loading if all of them are not verified, and they interrupt dispensing if one of them is not verified.

Should there be a need for additive treatment, TAS Nuovo Petrol allows additional checks to identify low levels in the additive tanks and faults in the loading pumps.

Loading data export to the erp system

The interface with the ERP system allows the automated dispatch of the final loading data and the scheduled shipments.

The ERP will then generate the necessary documents like the Simplified Accompanying Document for Excise Goods (SAAD).

Documents pick-up point

An automated system for drivers’ self-collection of loading documents.

The management of document collection synchronizes the driver’s access authorization to the document collection room with the printing of documents related to their shipment.

A WEB-BASED TAS SYSTEM FOR EFFORTLESS USE

Nuovo Petrol TMS technology guarantees hardware and management integrations with reliable data exchanges

NUOVO PETROL Terminal Automation System can be interfaced with the most popular ERP systems, management systems, and third-party field instrumentation such as flow computers, tank gauging systems, weighing stations, number plate recognition cameras (ANPR, LPR, OCR), RFID badge readers, biometric readers, PLCs, DCS, etc.

01

SIMULTANEOUS CONTROL OF THE ARMS

Simultaneous control up to 6 loading arms

02

LCD INTERFACE

15″ LCD interface to easily guide the driver through loading procedures

03

ADDITIVE MANAGEMENT

Additivation, denaturation and mixing management

04

FIELD DEVICES MANAGEMENT

I/O management and interface protocols for the automatic control of field devices

05

CUSTOMIZABLE INTERLOCKS

Customizable interlock logics and controls

06

REMOTE CONTROL

Remote control via TCP or RTU connection

07

SELF DIAGNOSTICS AND ALARMS

Hardware self-diagnostics and alarm management